Maximum speed - 60 tubes/min

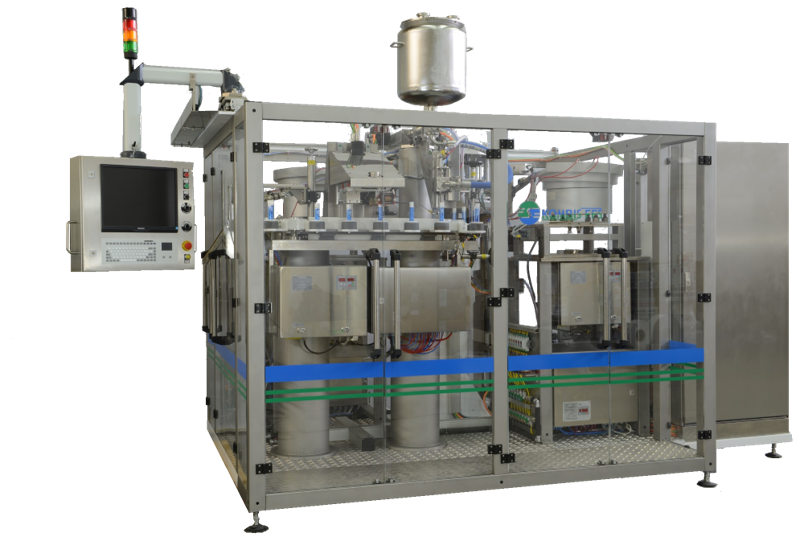

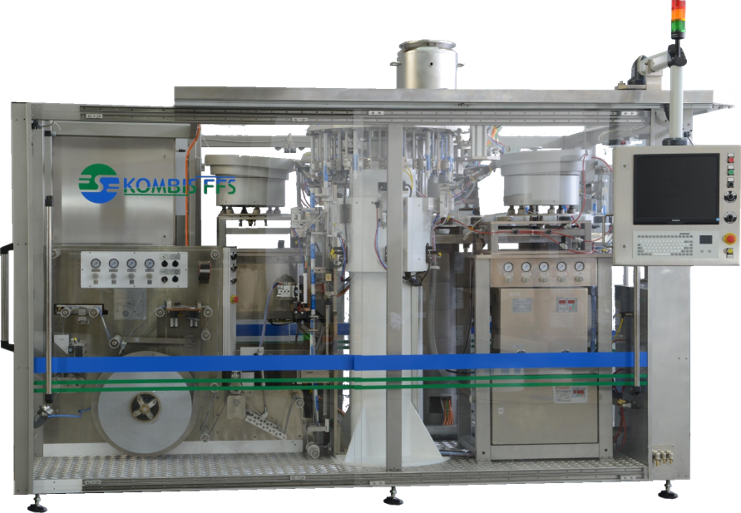

Kombis FFS60

The new FFS-60 design allows everything to be easily accessed, maintained and upgraded. Operators have good all-round visibility and access to all components.

Every Quality Count

Best Qualities

Simplest Design

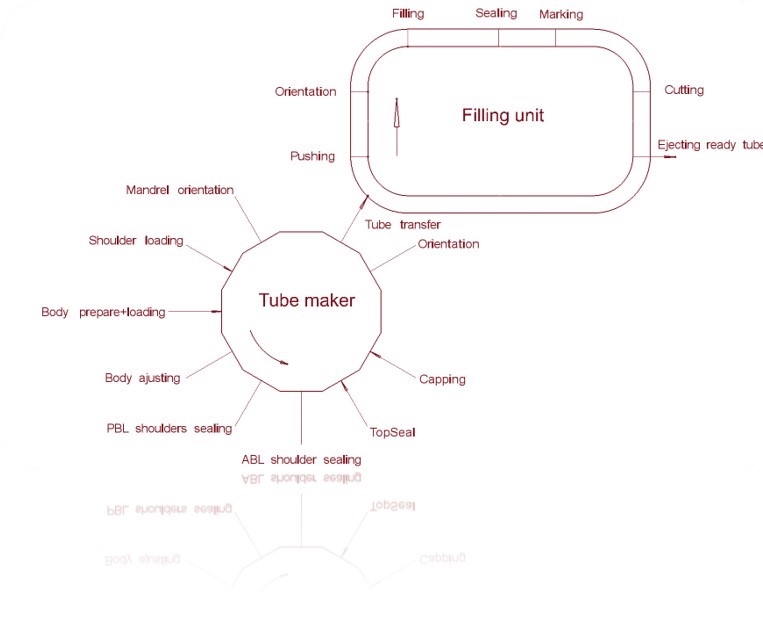

All processes are completed in steps; therefore stopping the FFS-60 is possible without any tube wastage.

Easy Tool Changeover

Different size parts are in kits ready for installing. No fine setting to change on machine. Just one technique is enough for 10 machines.

Easy product Exchange

All mechanisms in direct contact with the filling product can easily be removed from the FFS-60. Cleaning is done outside of the FFS-60. Second filling head is possible. Exchanging filling head for different product with different viscosity.

Why vertical

design?

In a classical designed machine it is difficult to access important machine components and parts.

The new FFS-60 design allows everything to be easily accessed, maintained and upgraded. Operators have good all-round visibility and access to all components. This reduces changeover time while maintaining the quality of settings.

Our Machine

Specifications

| Foil type | ABL and PBL |

| Foil total thickness | 0.175 - 0.330mm for ABL 0.300 - 0.400mm for PBL |

| Nominal speed | 60 ABL tubes / min 50 PBL tubes / min |

| Tube size | Tube Diameter Range: 16 -50 mm for ABL Tube Diameter Range: 22 - 50 mm for PBL Tube Length Range: 90 — 200 mm |

| Machine dimensions | Length: 3812mm Width: 3535mm Height: 2830mm |

| Variant 1 | Frame made from steel and aluminum profile. Good solution for: - technical products - hair dye - shampoo |

| Variant 2 | Frame made from steel and stainless steel. Good solution for: - cosmetic products - toothpaste - food products - medical products without special environmental requirements |

| Variant 3 | Whole machine made from steel and stainless steel. Plastic roof is included (for hygienic filling). Special system for foil disinfection before body forming. System for high precision filling with mass measure. |

| more | Note: For all of the variants, the filling components are made from steel 316L (1.4404, S31603, X2CrNiMo17-12-2) (1.4307, S30403, X2CrNi18-9) |